Understanding Hex Bolt Mechanics and Installation Principles

The Importance of Following Hex Bolt Installation Best Practices

Getting hex bolts installed correctly matters a lot for keeping structures intact. Studies show around 72 percent of problems with bolted joints happen because people didn't follow the right procedures. When workers stick to what manufacturers recommend and apply the proper torque according to standards, they get that important clamp load going between materials. Clamp load is basically what keeps everything from coming apart under stress. Skip these basics though, and things start going wrong fast. We've seen shear failures where bolts just snap clean through, fatigue cracks developing over time, and worst case scenario complete detachment from structures like bridges or heavy machinery components. These aren't theoretical risks either they happen every day when shortcuts are taken during installation.

Overview of the Fastener Installation Process and Its Critical Stages

The installation process consists of three essential phases:

- Preload Calculation – Determining required tension based on joint materials

- Tool Selection – Matching torque tools to bolt grade and size

- Sequential Tightening – Applying force in stages using cross-pattern sequences

Skipping any phase introduces friction variability, which can reduce load consistency by up to 35%, according to ASTM F16 committee research (2022).

Common Hex Bolt Installation Mistakes and How to Prevent Them

Over tightening risks and torque control: Consequences of exceeding yield strength

Exceeding a hex bolt’s yield strength causes permanent deformation, reducing clamp load by up to 40%. This creates stress concentrations that promote crack propagation in dynamic applications. Effective torque control includes:

- Using calibrated digital torque wrenches with ±3% accuracy

- Adjusting for lubrication effects, which reduce required torque by 15–25% (per ASTM F1941)

- Confirming bolt grade markings (e.g., Grade 5 vs. Grade 8) before use

Under tightening: The danger of insufficient preload and vibration loosening

Insufficient preload allows micro-movements that loosen joints over time. A 2023 failure analysis found 62% of vibration-related joint failures stemmed from torque values 20% below specifications. Mitigation strategies include:

- Applying threadlockers on standard nuts in high-vibration settings

- Using direct tension indicators (DTIs) for preload verification

- Scheduling retorquing after 24–48 hours for gasketed assemblies

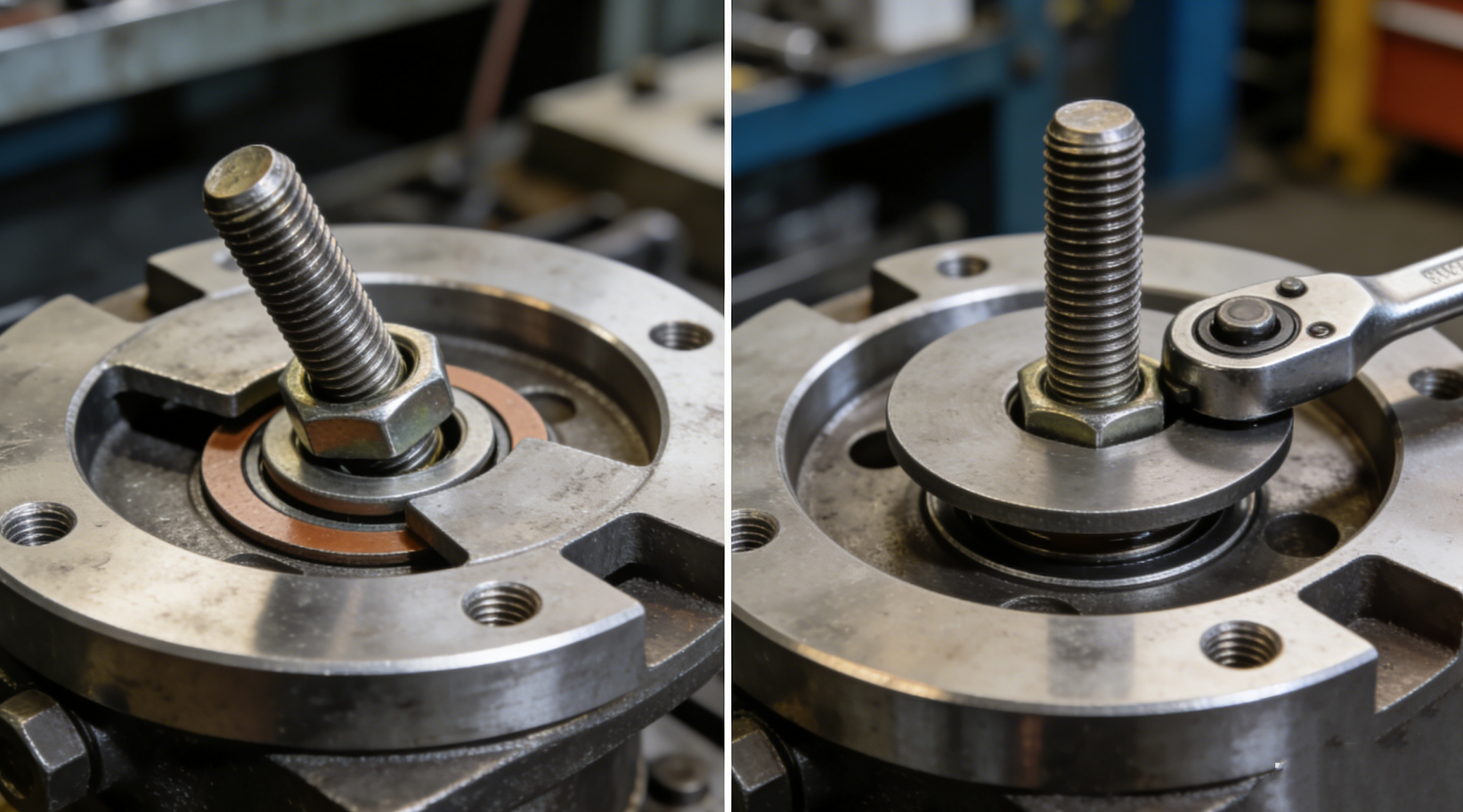

Impact wrenches vs. torque wrenches: Precision trade-offs in hex bolt applications

Impact wrenches offer speed but have ±25% torque variance, making them unsuitable for precision-critical joints like pressure vessels. Torque wrenches provide higher repeatability (±5%) but require:

- Recalibration every 5,000 cycles or annually

- Angular rotation techniques for hard metal interfaces

- Dual verification for torques exceeding 300 N·m

Emerging hybrid smart tools combine impact power with ultrasonic tension monitoring, reducing calibration drift by 70% compared to traditional mechanical wrenches.

Proper Torque Application: Tools, Techniques, and Best Practices

Calculating Correct Torque Values Based on Preload and Friction Coefficients

Getting accurate torque right begins with figuring out what numbers to actually represent. The equation T=KxDxF, where T is Torque, K is Friction Factor, D is Bolt Diameter, and F is the Desired Preload, helps calculate this. Small changes can cause significant differences in performance, as a change of 0.15 in the friction coefficient can cause a 35% shift in clamp load.

Selecting the Right Torque Tools for Consistent Hex Bolt Installation

| Tool Selection | Accuracy | Best Applications |

|---|---|---|

| Mechanical Click | ±4% | Aerospace/automotive |

| Hydraulic | ±2% | High-torque applications |

| Multipliers w/fixed heads | ±1% | Heavy-duty anchorage |

According to the torque guide, electronic wrenches reduce variability by 34% compared to mechanical wrenches.

Smart Torque Sensors: Enhancing Performance

Smart torque sensors are the latest in bolting technology. These sensors can detect even minor preload losses and provide real-time adjustments. A 2023 trial at an automotive plant reported a 92% reduction in joint failures after implementing sensor-assisted assembly.

Common Hex Bolt Installation Mistakes and How to Prevent Them

Impact wrenches vs. torque wrenches: Precision trade-offs in hex bolt applications

Choosing between impact wrenches and torque wrenches depends on the specifics of the job:

- Impact wrenches are faster but less accurate. They are suitable for less critical applications.

- Torque wrenches, while slower, provide greater precision and are ideal for jobs involving high precision requirements.

- For the best of both worlds, consider hybrid smart tools that use ultrasonic tension monitoring for accuracy while providing the speed of an impact wrench.

Proper Torque Application: Tools, Techniques, and Best Practices

A Consistent Approach to Bolt Installation

Following best practices ensures bolt integrity and equipment safety:

- Calculating accurate torque values according to specific joint applications

- Identifying and selecting the correct tools for the job, with regular calibration

- Executing sequential tightening strategies in stages to achieve optimal preload distribution

- Utilizing smart tools and sensors for enhanced monitoring

Verifying Hex Bolt, Nut, and Material Compatibility

Preventing Mechanical Failures through Correct Bolt Selection

Choosing the right bolts can prevent up to 23% of industrial mechanical failures. Fastener Engineering recommends the following:

- For steel materials, ensure 1.5 times thread engagement of bolt diameter

- For aluminum, 2 times thread engagement of bolt diameter is required

- Check for appropriate grade markings before installation to prevent mismatches

Importance of Interoperability in Fastener Standards

| Standard | Typical Use Case | Key Interoperability Factor |

|---|---|---|

| Standard | Typical Use Case | Key Interoperability Factor |

| ISO | Precision machinery | Metric thread pitch alignment |

Verify alignment between bolt pitch and thread specifications to reduce the risk of errors in international projects.

Pre-Installation and Verification of Hex Bolt Joints

- Implement a three-step cleaning protocol for joints: Clean, dry, and lubricate

- Use alignment tools like dowels or laser processes to ensure proper alignment

- Conduct post-tightening checks within 30 minutes to prevent being caught by settling and embedding

- Utilize ultrasonic tension measurement techniques post-installation

Table of Contents

- Understanding Hex Bolt Mechanics and Installation Principles

- Common Hex Bolt Installation Mistakes and How to Prevent Them

- Proper Torque Application: Tools, Techniques, and Best Practices

- Common Hex Bolt Installation Mistakes and How to Prevent Them

- Proper Torque Application: Tools, Techniques, and Best Practices

- Verifying Hex Bolt, Nut, and Material Compatibility