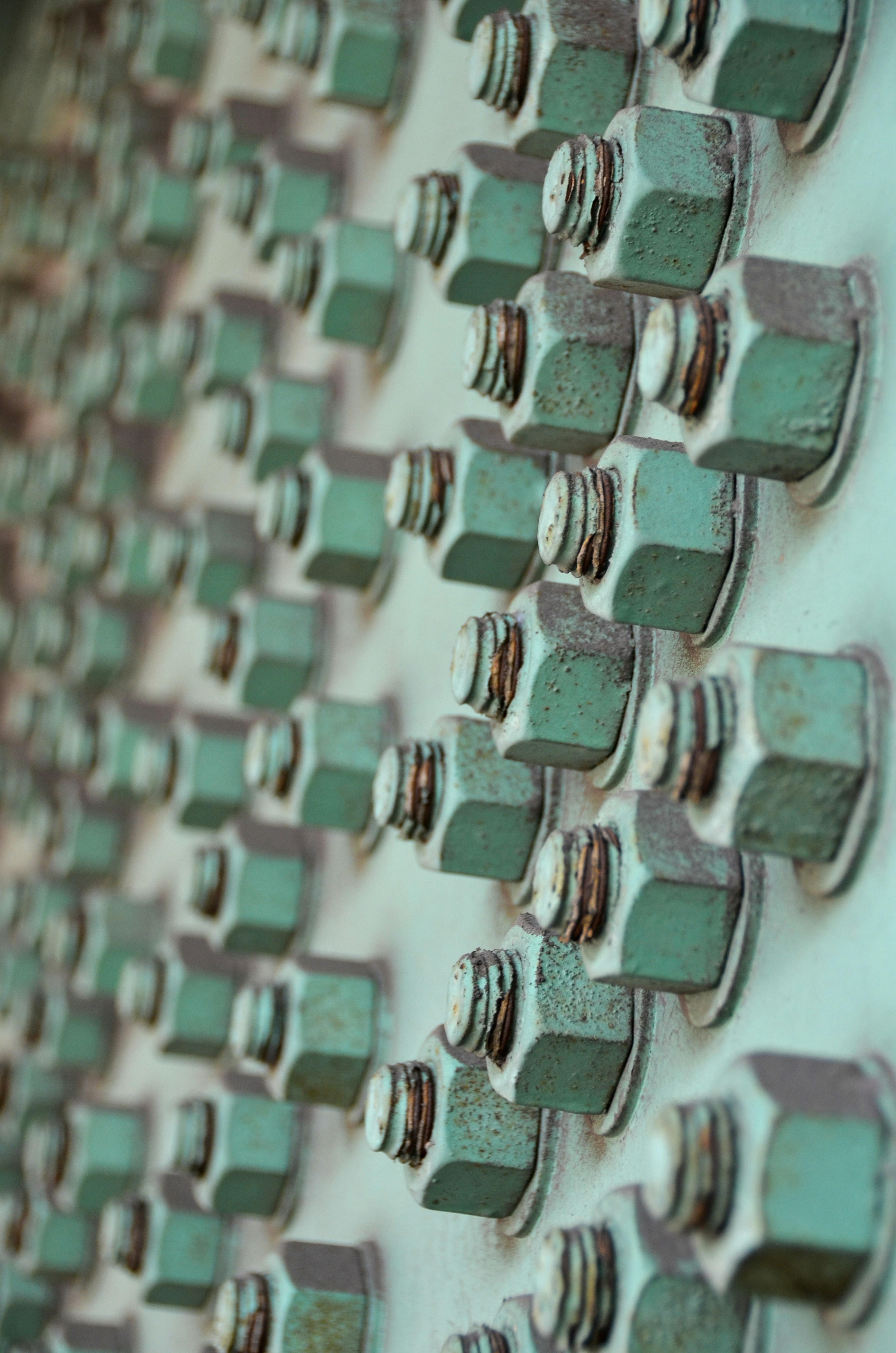

Understanding Corrosion in Stainless Steel Screws

Types of Corrosion: Pitting, Crevice, and Galvanic

Stainless steel screws face three primary corrosion threats in industrial applications:

- Pitting corrosion: Chloride ions common in seawater or de-icing salts penetrate the metal’s passive chromium oxide layer, forming small, deep pits that compromise structural integrity.

- Crevice corrosion: Develops in oxygen-deprived gaps between screw heads and mating surfaces, where stagnant moisture promotes localized chemical attack.

- Galvanic corrosion: Occurs when stainless steel contacts dissimilar metals like aluminum or carbon steel in the presence of an electrolyte, triggering electrochemical degradation.

Why Stainless Steel Isn’t Completely Corrosion-Proof

Although stainless steel contains at least 10.5% chromium to form a self-repairing oxide layer, this protection weakens under mechanical stress, acidic conditions (pH < 1.5), or prolonged chloride exposure. For instance, 304-grade screws can begin to degrade in saltwater environments within 6—12 months without proper maintenance.

Environmental Conditions Affecting Screw Performance

Marine atmospheres accelerate pitting corrosion five times faster than arid climates due to airborne salinity. Temperatures exceeding 140°F (60°C) reduce oxide layer stability, while acidic industrial fumes (pH < 2) cause uniform surface erosion. In coastal wastewater treatment plants, quarterly inspections are essential to manage these combined risks.

Selecting the Right Grade of Stainless Steel Screws

Choosing the optimal stainless steel grade is critical for ensuring long-term corrosion resistance. While all grades rely on chromium for passivation, alloy enhancements significantly influence performance in aggressive environments.

Comparing 304 vs 316 Stainless Steel for Different Environments

Grade 304 (A2), with 18% chromium and 8% nickel, offers reliable protection in indoor or mild settings at a lower cost. Grade 316 (A4) includes 2—3% molybdenum, greatly improving resistance to chlorides and acids. Accelerated testing shows 316 withstands saltwater exposure four times longer than 304.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Key Alloy | Chromium-Nickel | Chromium-Nickel-Moly |

| Chloride Tolerance | Up to 200 ppm | Over 1,000 ppm |

| Ideal Use Cases | Dry interiors, appliances | Coastal construction, chemical processing |

Matching Screw Grade to Application for Maximum Durability

Selecting the right grade based on environment extends service life by 60—80% in high-humidity installations:

- 304 screws: HVAC systems, indoor furniture, commercial kitchens

- 316 screws: Boat fittings, pharmaceutical equipment, pool hardware

- 430 screws: Automotive trim, seasonal outdoor structures

Cross-reference operating conditions with manufacturer corrosion charts and verify galvanic compatibility in mixed-metal assemblies to prevent premature failure.

Routine Cleaning and Contamination Prevention

Contaminants such as iron particles or chlorides can reduce stainless steel’s corrosion resistance by up to 40%, making regular maintenance essential.

Effective Cleaning Methods and Maintenance Schedules

Clean with pH-neutral solutions and soft nylon brushes to avoid surface damage. In high-humidity areas, monthly cleaning prevents chloride buildup that accelerates pitting. Industrial settings with frequent thermal cycling may require biweekly inspections to maintain oxide layer integrity.

Removing Surface Contaminants Like Iron Particles and Dust

Iron residue from carbon steel tools can initiate rust spots. Remove debris using compressed air (<30 PSI) before cleaning. After saltwater exposure, rinse with distilled water within four hours to neutralize corrosive chlorides.

Best Practices for Handling and Storing Stainless Steel Screws

Store screws in sealed containers with silica gel desiccants, replacing packs every 90 days. Wear nitrile gloves during handling—skin oils can impair repassivation by 18% in humid conditions.

Inspection Routines to Catch Early Signs of Degradation

Monitor for:

- Discoloration (straw-yellow to blue hues signal oxide damage)

- Thread galling from inadequate lubrication

- Salt crystallization around fastener heads in marine zones

Replace screws exhibiting over 10% surface pitting or stress corrosion cracking at load points.

Preventing Galvanic Corrosion in Mixed-Metal Assemblies

Avoiding Contact Between Stainless Steel Screws and Dissimilar Metals

When stainless steel connects with metals like aluminum or copper in wet environments, galvanic corrosion rapidly degrades the less noble material—aluminum corrodes up to ten times faster in saltwater (Marine Materials Study 2023). Mitigation strategies include:

- Isolating metals with nylon washers or polymer gaskets

- Selecting compatible materials closer in the galvanic series, such as pairing stainless steel with bronze instead of aluminum

Using Insulation and Barriers to Stop Galvanic Reactions

Dielectric barriers interrupt ionic current flow. Effective methods include:

- Applying dielectric compounds like TefGel® to threads

- Installing neoprene sleeves on fasteners in mixed-metal joints

Anodized aluminum coatings have been shown to reduce galvanic corrosion by 89% when used with stainless steel hardware.

Real-World Example: Failure Prevention in Marine Fastening Systems

A 2024 analysis of offshore platforms found that combining 316 stainless steel screws with insulating PET sleeves reduced galvanic failures by 93% over five years. Key measures included:

- Encapsulating screw threads in silicone-based sealants

- Implementing quarterly checks for coating integrity

- Replacing standard washers with ceramic-embedded versions in high-salinity areas

Pro Tip: In coastal installations, use sacrificial zinc anodes alongside stainless steel fasteners to divert corrosive activity away from critical components.

Lubrication and Thread Maintenance for Reliable Performance

Applying Anti-Seize Compounds to Prevent Galling and Seizing

Nickel-based anti-seize lubricants reduce friction by 30—50% in stainless steel fasteners, according to a 2023 NACE International study. These compounds prevent thread galling a condition where stainless steel surfaces cold-weld under pressure. Apply a thin, even layer to threads using brushes or automated dispensers, especially at interfaces involving dissimilar metals.

Proper Techniques for Lubricating Stainless Steel Screws

Degrease threads with acetone or isopropyl alcohol before application to ensure adhesion. Controlled lubrication methods extend fastener lifespan by 18—24 months in coastal environments. For high-torque applications, use molybdenum disulfide-based greases, which retain viscosity better than petroleum alternatives at elevated temperatures.

Common Lubrication Mistakes and How to Avoid Them

- Over-application: Excess lubricant traps abrasive contaminants—wipe excess with lint-free cloths post-assembly

- Mixing incompatible formulas: Silicone-based products can degrade zinc-plated parts in mixed-metal systems

- Ignoring environmental factors: In saltwater conditions, reapply lubricant 40% more frequently than in dry climates

A 2022 marine fastener case study showed that following proper lubrication protocols reduced galling incidents by 65% compared to untreated assemblies. Always refer to manufacturer guidelines for torque adjustments based on your lubricant’s friction coefficient.

FAQ Section

Why do stainless steel screws corrode?

Stainless steel screws corrode primarily due to exposure to chloride ions, environmental stress, acid conditions, or contact with dissimilar metals, leading to various types of corrosion such as pitting, crevice, or galvanic corrosion.

Is stainless steel completely corrosion-resistant?

No, stainless steel isn’t completely corrosion-resistant. Its protective oxide layer can break down under specific conditions like mechanical stress, acid exposure, or prolonged contact with chlorides.

How can I prevent galvanic corrosion in mixed-metal assemblies?

To prevent galvanic corrosion, avoid direct contact between stainless steel and dissimilar metals, use isolation methods like nylon washers, and apply dielectric barriers or compounds.

What are effective ways to clean stainless steel screws?

Effective cleaning involves using pH-neutral solutions and nylon brushes, monthly cleanings in humid areas to prevent chloride buildup, and rinsing with distilled water after saltwater exposure.

Table of Contents

- Understanding Corrosion in Stainless Steel Screws

-

Selecting the Right Grade of Stainless Steel Screws

- Comparing 304 vs 316 Stainless Steel for Different Environments

- Matching Screw Grade to Application for Maximum Durability

- Routine Cleaning and Contamination Prevention

- Effective Cleaning Methods and Maintenance Schedules

- Removing Surface Contaminants Like Iron Particles and Dust

- Best Practices for Handling and Storing Stainless Steel Screws

- Inspection Routines to Catch Early Signs of Degradation

- Avoiding Contact Between Stainless Steel Screws and Dissimilar Metals

- Using Insulation and Barriers to Stop Galvanic Reactions

- Real-World Example: Failure Prevention in Marine Fastening Systems

- Lubrication and Thread Maintenance for Reliable Performance

- FAQ Section