Die geskikte kies van befastings vir komponente hou 'n produksielyn glad en doeltreffend aan die gang om uitvaltye te vermy. Hierdie artikel bespreek hoe om befastings te kies met inagneming van materiaal en grootte om aan die meeste van u behoeftes te voldoen.

Verstaan van Befastings

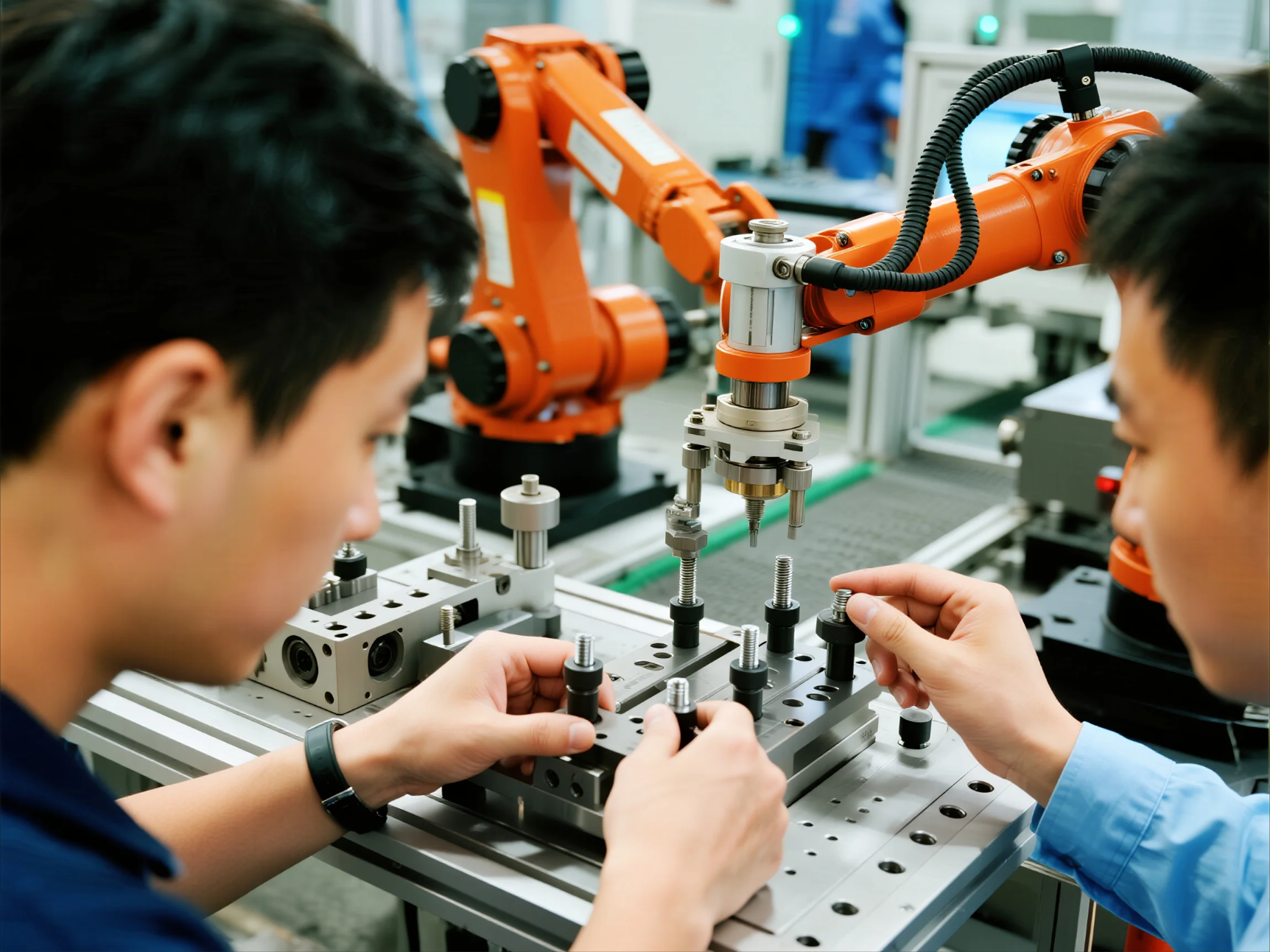

Vasleggers is baie belangrik in 'n produksie lyn om twee of meer dele aan mekaar te heg. Hulle kom in die vorm van skroewe, boute, moere en nieties voor. Die keuse van vasleggers kan 'n groot verskil in die produk se waarde maak. Wanneer jy vasleggers kies, is dit belangrik om die behoeftes van jou toepassing, die las, blootstelling aan buite-elemente en die materiale wat saam daarmee gebruik word, te bepaal.

Materiaal Keuse

Een van die kwessies rakende al hierdie vasleggers is die materiale. 'n Vaslegger kan van metale, plastiek of 'n samestel gemaak word, elk met sy eie voordele. Byvoorbeeld, vasleggers van roesvrye staal word buite gebruik omdat hulle vasleggers is, en plastiekmateriale word in rowwe omgewings gebruik omdat dit lig en weerstandsbiedend teen chemikalieë is. Om hierdie materiale en hul eienskappe sowel as swakhede te ken, sal help om duursame produkte te ontwerp.

Grootte en Skroefdraad

Die grootte sowel as die spasering van die bevestigingsbout se draad is kritieke aspekte waarop aandag moet word. Bevestigers word in verskillende deursnee en lengtes aangebied. Die verkeerde grootte bevestiger kan lei tot katastrofiese strukturele faling. Wanneer 'n bevestiger gekies word, moet daar rekening gehou word met die totale dikte van die dele wat aan mekaar vasgemaak moet word, asook hul saamgevoegde dra-vermoë. Daarbenewens het die tipe draad, of dit nou fyn of growwe draad is, ook 'n impak op die bevestigingssterkte en grypkrag. Fyn draad word verkies in hoë sterkte toepassings, terwyl growwe draad verkies word in sagter materiale.

Toepassingsspesifieke oorwegings

Verskillende toepassings mag spesifieke bevestigingsmiddels vereis vir hulle om sonder probleme te werk. Byvoorbeeld, in hoë vibrasie-omgewings, kan sluitbevestigings of bevestigingsmiddels met spesiale coatings wat ontwerp is om hulle veilig te hou, benodig word. Aan die ander kant, toepassings wat blootgestel is aan ekstreme koue of hitte vereis spesiale bevestigingsmiddels wat skadelike temperature kan weerstaan. 'n Begrip van die spesifieke vereistes van die bevestigingsmiddel sal help die ontwerper om die bevestigingsmiddels te kies wat nie net sal voldoen nie, maar ook sal oortref.

Kwaliteitsversekering en toetsing

Wanneer bevestigingsmiddels bestel word, is dit ewe belangrik om te verseker dat gehalteborgstellingmetodes gebruik is. dit kan insluit toetse vir sterkte en korrosie vir meer sekerheid. Dit is ook belangrik om vertroude leweraars te hê wat binne die industriële standaarde werk om sodoende die veiligheid en betroubaarheid van die bevestigingsmiddels wat in produkte gebruik gaan word, te verseker.

Bedryfsriglyne en Innovasies

Elke dag verskyn nuwe materiale en tegnologieë wat die behoeftes van vervaardigingsmaatskappye bevredig. As gevolg hiervan, maak elke vervaardiger dit 'n punt om op datum te bly, aangesien die bevestigingsmiddels aansienlik gevorder het in die afgelope jare. 3D-druk en geavanseerde bevestigingsmiddels met bedekkings is sommige van die innovasies wat reeds ingespan is. Hierdie bevestigingsmiddels het die produksie van bevestigingsmiddels heeltemal geïllustreer.