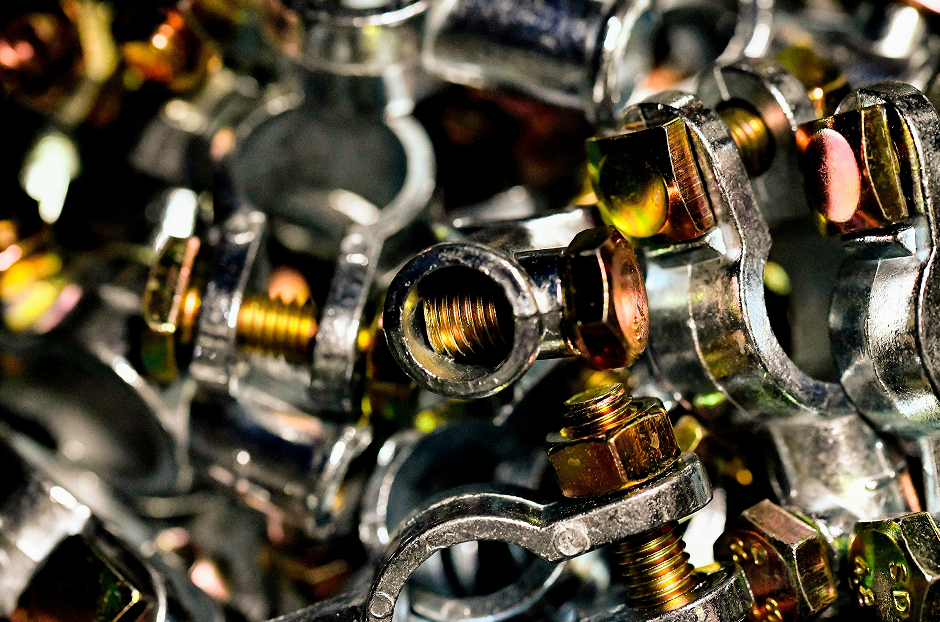

High Tensile Strength and Load Bearing Capacity of Hex Bolts

The six sides of hex bolts give them some serious strength when it comes to holding things together. Compared to those old square head fasteners, they can take about 35% more torque before giving way. The shape spreads out the pressure pretty evenly across all surfaces. Take ASTM A574 grade bolts for instance these babies can handle tension forces over 200,000 pounds per square inch. When we look at real world applications in big machines and equipment, studies show around 18% fewer breakdowns happen with hex bolts versus traditional rivet connections according to Ponemon's research from last year. Most engineers will tell anyone who asks that hex bolts just make sense for important parts where failure isn't an option.

Durability Under Vibration and Dynamic Stress in Machinery Systems

Machinery operating above 1,500 RPM subjects fasteners to intense harmonic vibrations, often leading to premature failure within 6–12 months for lower grade options. Hex bolts resist loosening through key design and manufacturing advantages:

- Thread pitch optimization: Coarse threads maintain grip under lateral movement

- Flanged designs: Integrated washers reduce fretting corrosion by 62%

- Precision manufacturing: Cold forged shoulders withstand deformation at temperatures exceeding 400°F

Field tests in aggregate crushers show that joints secured with hex bolts last 2.3 times longer than welded connections under identical vibration conditions, highlighting their superior fatigue resistance.

Comparison With Alternative Fasteners: Why Hex Bolts Excel in Reliability

| Fastener Type | Torque Precision | Vibration Resistance | Corrosion Tolerance |

|---|---|---|---|

| Hex Bolt | ±5% | 850+ hrs (ASTM D7774) | CR4+ (ISO 9227) |

| Socket Head Cap Screw | ±15% | 600 hrs | CR3 |

| Carriage Bolt | ±25% | 300 hrs | CR2 |

Hex bolts outperform alternatives due to 360° wrench engagement and standardized sizing. In automotive transmission mounts, socket head cap screws failed 42% faster during thermal cycling tests, underscoring the reliability advantage of hex bolts in dynamic environments.

Material and Environmental Resilience of Hex Bolts

Selecting Hex Bolt Materials for Extreme Temperatures and Corrosive Environments

The choice of materials makes all the difference when it comes to how well hex bolts hold up under tough conditions. Take stainless steel for instance it stands up pretty well against saltwater corrosion which is why we see it so much in boats and other marine equipment. Alloy steels are another story they work great in those really hot environments like industrial furnaces where temperatures can swing from below freezing at 40 degrees Fahrenheit right up to scorching 800 degrees Fahrenheit. Some recent research published last year looked at fastener durability and found something interesting about titanium hex bolts. These special bolts cut down on failures by around two thirds in parts used for airplanes that get subjected to repeated heating and cooling cycles. That kind of performance explains why manufacturers in aerospace and other demanding industries keep turning back to titanium despite its higher price tag.

Protective Coatings and Finishes That Enhance Longevity in Harsh Conditions

Advanced coatings extend service life beyond base material limits:

| Coating Type | Corrosion Resistance | Max Temperature Threshold | Ideal Application |

|---|---|---|---|

| Hot Dip Galvanized | 15+ years | 390°F (199°C) | Offshore platforms |

| Xylan® Polymer | 8x base metal | 500°F (260°C) | Chemical processing tanks |

| Black Oxide | Moderate | 300°F (149°C) | Indoor machinery |

| Electroless Nickel | Severe | 750°F (399°C) | Power plant turbines |

Hot dip galvanized hex bolts last 3.2 times longer than uncoated versions in coastal infrastructure, and industry standards require a minimum zinc coating thickness of 0.0039" for structures exposed to de icing chemicals.

Precision Engineering: Sizing, Threading, and Torque Control

Matching Hex Bolt Dimensions and Thread Types to Machinery Requirements

Around 72% of joint failures happen because components aren't sized correctly according to the Machinery Reliability Report from 2023. Most engineers turn to ISO 898 1 when they need to get thread pitch and diameter right so loads spread evenly across connections. For parts that spin around like motors or pumps, fine thread hex bolts (those UNF ones) stand up better to vibrations over time. Coarse threads (UNC type) work great where there's lots of tension holding structures together. When manufacturers use laser measurements to profile those threads, they cut down on stress points by roughly 30%. This makes a big difference in things like gearboxes and hydraulic systems where reliability is absolutely critical.

Importance of Correct Torque Application to Ensure Joint Integrity

The problem of incorrect torque is costing industries around $4.8 billion each year according to Plant Engineering Journal figures from 2023. Most professionals stick to ASTM F568M 2022 specs when tightening components, especially since hydraulic tensioning equipment can hit within about 2% accuracy for those really important jobs like securing wind turbine flanges. When technicians apply too much force, it actually creates tiny cracks in high strength Grade 8 bolts over time. On the flip side, not enough torque means parts just work themselves loose through vibration issues commonly seen in CNC machines. These days, many advanced torque control setups come with built in strain gauges that provide instant feedback, allowing workers to make fine adjustments as robots put together engine blocks and transmission systems on production lines.

Key Industry Applications: Automotive, Aerospace, and Heavy Equipment

Hex bolts are essential in industries where mechanical reliability directly impacts safety and performance.

Critical use of hex bolts in automotive manufacturing and assembly lines

Hex bolts have become the go to choice in automotive manufacturing for engine blocks and suspension systems because they hold about 30 percent more torque compared to those old Phillips head screws. Modern robotic assembly lines can fit M12 to M24 hex bolts with nearly 98% accuracy these days, especially when putting together the complex frames of electric vehicles. The level of precision makes a real difference too reducing component misalignment problems by around two thirds during fast paced production runs. This means better quality control across the board and stronger structural components that meet safety standards consistently throughout the manufacturing process.

Aerospace applications: Hex bolts vs. socket head cap screws in performance contexts

When it comes to turbine frames and wing spar joints, aerospace engineers often go with hex bolts because those six sided heads make tools get to work about a quarter faster compared to socket head cap screws. Both types satisfy MIL SPEC standards sure enough, but there's something special about how hex bolts deal with repeated stress in cryogenic fuel valves they just take on about forty percent more load cycles before showing wear. The standard drive design is another plus point too, especially when putting satellites together in space where having consistent tool compatibility really cuts down on headaches for technicians dealing with all sorts of complicated hardware configurations floating around zero gravity.

Heavy hex bolts in construction and industrial machinery with high load demands

When dealing with really heavy loads, most engineers go for ASTM A490 heavy hex bolts for things like crane boom pivots and those big mining shovel connections. We're talking about bolts with diameters well above 50mm in these situations. Now interestingly enough, galvanized versions of these heavy hex bolts hold onto about 92% of their original tension even after sitting out there for 15 years on offshore drilling platforms. That's roughly 35% better than regular hex bolts would manage under similar conditions. The bigger bearing surface on these bolts actually distributes the dynamic forces over around 40% more threads compared to standard bolts. This makes all the difference when it comes to keeping joints intact in massive equipment like 25 ton hydraulic press frames where failure just isn't an option.

Global Standards and Compliance for Hex Bolt Use in Machinery

Adherence to ISO, ASTM, and DIN standards in hex bolt manufacturing

Getting consistent performance out of industrial components really comes down to sticking with established international standards. Most manufacturers rely on ISO 9001 quality management systems to keep their products meeting minimum tensile strength requirements, typically staying well above 800 MPa which is essential for things like construction projects and heavy machinery operations. When it comes to threaded connections, DIN 933 sets strict guidelines about thread tolerances within just ±0.1mm, plus full thread designs that actually stand up better to vibrations compared to regular fasteners, improving resistance by around 18%. For extreme environments, ASTM A574 certification ensures alloy steels can handle temperatures from as low as 50 degrees Celsius all the way up to 300 degrees without compromising their grip. Independent testing labs regularly check Rockwell hardness levels between 35 and 45 HRC while also confirming proper chemical makeup. Industry reports show that failing to meet these standards accounts for roughly one quarter of all fastener failures according to findings published in Industrial Safety Review back in 2023.

Ensuring traceability and certification in B2B supply chains

Good suppliers these days are implementing blockchain technology to track products at each step along the supply chain, starting right from where materials come from all the way through to how they're treated against corrosion. The aerospace industry needs detailed records following AS9100D standards for things like heat treatment between 400 and 450 degrees Celsius plus ultrasonic tests. Car manufacturers want their parts suppliers to submit PPAP packages showing proper torque tension measurements and salt spray resistance according to ASTM B117 specifications. Recent market research shows that around two thirds of people buying big machinery look specifically for suppliers certified under IATF 16949 standards, something that actually cuts down on factory errors by about 40 percent. Most companies have moved away from paper files altogether, switching instead to digital test reports that make checking if batches meet requirements much faster when moving goods across borders or through warehouses.

Table of Contents

- High Tensile Strength and Load Bearing Capacity of Hex Bolts

- Material and Environmental Resilience of Hex Bolts

- Precision Engineering: Sizing, Threading, and Torque Control

- Key Industry Applications: Automotive, Aerospace, and Heavy Equipment

- Global Standards and Compliance for Hex Bolt Use in Machinery