How High Strength Bolts Work: Principles and Mechanical Properties

The fundamental principle of high strength bolts: clamping force and preload

Strong bolts hold structures together using what engineers call controlled preload, basically an exact amount of force applied when tightening them down. What happens is this preload pushes the connected parts together so tightly that the friction between them actually helps transfer loads across the joint. According to various engineering studies, these high strength connections work best when around 70 to 90 percent of the bolt's maximum strength is used for this initial tensioning. That leaves enough compression in place so the connection stays solid even when outside forces start pulling at it from different directions.

Mechanical properties of high strength bolts: tensile strength, yield strength, and hardness

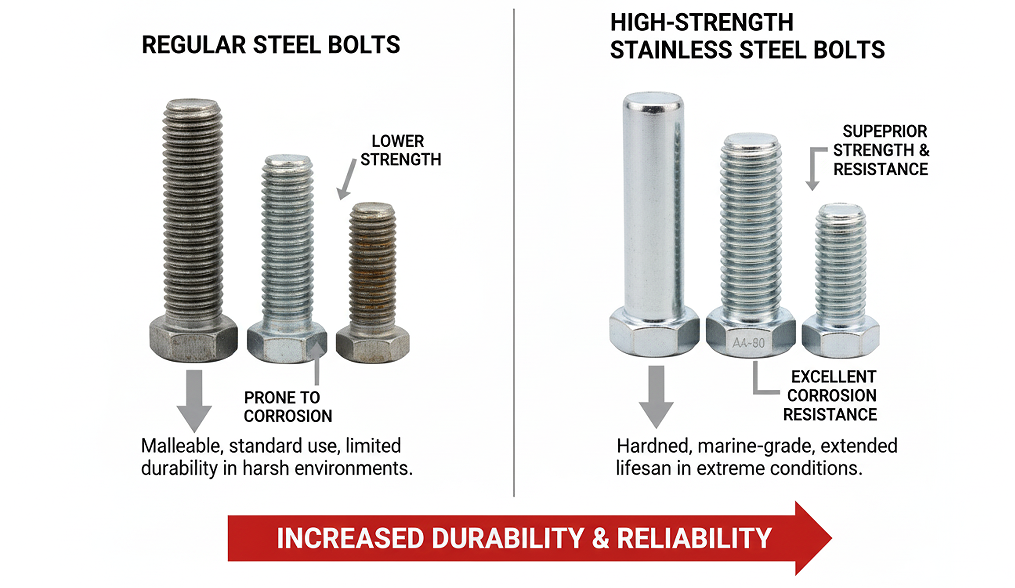

The ISO Grade 10.9 and 12.9 bolts are real workhorses when it comes to strength, hitting over 1,040 MPa in tensile strength which beats the heck out of regular Grade 5 bolts at around 830 MPa. For bridges and other heavy duty structures, ASTM A490 bolts are the go to choice. They need to hold up under serious stress, so they're built to maintain at least 150 ksi yield strength. What's interesting is how they manage to keep their Rockwell C hardness between 33 and 39 too, which means they resist wearing down even after years of service. This combination of strength and durability makes all the difference in earthquake prone areas where bolts can stretch and fail if not properly specified. Engineers know this stuff matters because one weak link in the chain can bring everything crashing down during seismic events.

Toughness and ductility requirements for reliable structural performance

High strength bolts balance hardness with Charpy V notch impact values >27 J at 40°C. This ductility prevents brittle fracture during thermal cycling or shock loading—critical in wind turbine foundations and offshore platforms.

Frictional force in bolt connections: role in load transfer efficiency

The clamped joint's slip resistance depends on surface preparation and preload. Grit blasted steel joints achieve friction coefficients (µ) of 0.45–0.55, enabling load transfer through pure friction rather than bolt shear. Properly tensioned A325 bolts in slip critical connections sustain 40–50 kN/m² shear loads without slippage.

Comparison of ASTM A325 and ASTM A490 specifications in real world applications

| Property | ASTM A325 | ASTM A490 |

|---|---|---|

| Minimum Tensile Strength | 825 MPa | 1,035 MPa |

| Typical Applications | General construction | Heavy machinery mounts |

| Corrosion Resistance | Medium (zinc plated) | High (hot dip galvanized) |

| Max Service Temperature | 149°C | 204°C |

A325 bolts dominate in building frames due to cost effectiveness, while A490’s superior strength to weight ratio makes it ideal for telescopic crane booms and transmission towers. Both require calibrated tensioning tools to achieve ±5% preload accuracy.

Superior Load Capacity and Long Term Structural Integrity

How High Strength Bolts Improve Load Distribution in Steel Structures

When it comes to distributing loads effectively, high strength bolts work their magic through controlled preload forces that spread out the clamping pressure evenly across whatever components they're connecting. Regular bolts just sit there relying on shear resistance, but high strength versions keep things stable by maintaining good friction between steel plates, even when forces are changing around them. The difference is pretty significant too engineers report seeing about a 40 percent improvement in how loads get shared when these bolts are properly tightened according to specs. This helps avoid those pesky stress hotspots that can develop at connection points over time.

Case Study: Load Capacity Analysis in a Multi Span Bridge Using High Strength Bolts

Research conducted on the Lakeway Bridge retrofit in 2023 highlighted how high strength bolts can manage complicated loading conditions. When engineers swapped out around 18 thousand regular bolts for ASTM A490 versions, the bridge held up against wind forces reaching 850 kilonewtons per square meter, which is actually 62 percent higher than what it was originally designed for. Even after a full year under constant vehicle weight and movement, these improved bolted joints remained almost completely unchanged in shape. This kind of performance makes them particularly valuable when working on important structures where safety margins need to be maximized.

Data Comparison: Failure Thresholds of Standard vs. High Strength Bolts Under Stress Testing

| Property | ASTM A325 Bolt | ASTM A490 Bolt | Improvement |

|---|---|---|---|

| Tensile Strength (MPa) | 830 | 1040 | 25% |

| Yield Strength (MPa) | 635 | 940 | 48% |

| Fatigue Cycles @ 350MPa | 120,000 | 450,000 | 275% |

Role of Preload in Maintaining Long Term Structural Integrity

When preload forces are kept up to spec, they function like an ongoing maintenance system that automatically adjusts for materials losing tension over time and deals with changes in temperature or humidity. Take buildings or bridges with those specially calibrated high strength bolts tests show these connections still hold about 92% of their original tightness even after ten years on site, while regular bolts drop down to around 67%. The difference matters because this maintained grip stops water from getting into joints and stops tiny movements between parts that slowly wear everything apart. For engineers looking at long term structural integrity, keeping those preloads intact is absolutely critical.

Vibration and Dynamic Load Resistance in Critical Infrastructure

Why High Strength Bolts Outperform Conventional Fasteners Under Cyclic Loading

In dynamic environments where things get shaken up constantly, high strength bolts really stand out because they strike just the right balance between being strong under tension and resisting fatigue over time. Regular bolts tend to develop those tiny cracks after about 50 thousand stress cycles or so, but these stronger versions keep holding together thanks to their improved yield strength of at least 150 ksi plus better control over how much they can stretch before breaking. What makes them work so well? The secret lies in adding special ingredients during manufacturing such as boron and chromium. These elements help create finer grain structures within the metal itself, making it much harder for vibrations to concentrate stress in one spot and cause failure down the road.

Applications in Bridges and High Rise Buildings Where Vibration Resistance Is Critical

High strength bolts have made a real difference in San Francisco's efforts to make buildings safer against earthquakes. Tests showed these bolts cut down on joint movement by around 30 35% when compared with older fastening methods during simulated quake conditions. What makes them so effective is their ability to maintain consistent pressure, which stops those tiny metal to metal movements that lead to corrosion problems in bridge cables. This was especially important for the recent upgrades at the Golden Gate Bridge back in 2023. Looking upward, tall buildings also benefit from this tech. The famous Taipei 101 tower actually incorporates Grade 10.9 bolts into its massive damping system. These specialized fasteners handle incredible forces up to about 35 kilonewton meters of twisting motion even when typhoon winds start shaking the structure. Engineers love how reliable they are in these extreme situations.

Balancing Stiffness and Brittleness: Considerations for Seismic Zone Applications

For Alaskan pipeline supports, engineers often go with ASTM A490 bolts that have at least 27 Joules of Charpy V notch toughness when tested at minus 30 degrees Celsius. These specs help prevent cracks from forming when pipelines vibrate under heavy ice loads. Across the Pacific, Japanese architects working on skyscrapers are turning to modified A325 bolts instead. These special bolts pack around 120 ksi of tensile strength but still manage to stretch about 15 percent before breaking, which makes them great at soaking up earthquake energy without snapping suddenly. The combination really matters in base isolation systems. When big quakes hit (magnitude 7 and above), the bolts need to handle plus or minus 300 millimeters of movement back and forth. At the same time, they must keep their grip strong enough so the preload stays above 75 percent of what it was originally set to. Getting this right means buildings can sway safely without coming apart at the seams.

Friction Type vs. Bearing Type High Strength Bolt Connections

Key differences between friction type and bearing type high strength bolt connections

Friction connections work by applying clamping pressure that creates friction at the contact surfaces between materials, which stops them from slipping even when subjected to substantial loads. Bearing type connections are different because they let there be some small amount of movement before the bolts actually touch the sides of their holes. According to various engineering reports, friction connections generally need much higher initial tension forces around 70% of what the bolt can handle before it yields just to get enough grip. On the other hand, bearing connections focus more on how strong the bolts are against sideways forces, following specifications outlined in those ASTM standards for structural bolts like A325 and A490 that many construction projects require.

Performance comparison under shear and tension loads in steel frameworks

When dealing with shear loads, friction type connections tend to hold up better against fatigue because they spread out the stress over their contact surfaces. This makes them really important for things like suspension bridges where structural integrity matters most. Tests on steel frameworks from last year showed that bearing type connections actually have about 18 to 22 percent greater tensile strength when承受静态载荷. However, both kinds of connections need pretty accurate hole alignment during installation. What's interesting is that bearing type joints can tolerate small misalignments better than friction ones, allowing for gaps up to around 1.5 millimeters without compromising performance too much. Engineers often consider this tolerance factor when deciding which connection method works best for specific construction projects.

Selection criteria based on construction project requirements

- Choose friction type for applications with dynamic/vibrational loads (e.g., railway bridges, seismic zones)

- Opt for bearing type in static load structures requiring maximum shear capacity (e.g., building columns, industrial platforms)

- Prioritize material compatibility—ASTM A354 bolts with matching A563 nuts for both types

- Consider maintenance accessibility, as bearing type connections tolerate slight looseness better over decades of service

Standards, Materials, and Real World Benefits of High Strength Bolts

Overview of key standards: ISO 898 1, ASTM A325, A490, and A354

The specs for high strength bolts are pretty much set by strict international standards because nobody wants structures failing unexpectedly. Take ISO 898 1 for instance it lays out all those mechanical requirements including tensile strength which needs to be at least 1,000 MPa for Grade 12.9 bolts plus those important yield ratios that matter so much when buildings need to withstand earthquakes. Over in North America most folks still rely on ASTM A325 and A490 standards for their structural work. The A490 bolts actually handle shear forces about 20 to maybe even 30 percent better than regular A325 bolts depending on how they're used. There's also this newer standard called A354 Grade BD that specifically tackles thread fatigue issues. This matters a lot for things like wind turbine foundations where the bolts get hammered by constant back and forth movement from the wind over years of operation.

Common materials and grades for high strength nuts and bolts in heavy construction

The construction world relies heavily on alloy steels packed with chromium, molybdenum, and boron for their strength. When talking about medium carbon steel with around 0.25 to 0.55% carbon content, these materials typically reach Grade 8.8 after undergoing quenching followed by tempering processes. For those needing even stronger options like Grade 12.9 bolts, manufacturers turn to chrome molybdenum alloys which need special hardening treatments bringing them up to between 39 and 44 on the Rockwell scale. Something interesting happening lately is the development of weathering steel bolts containing approximately 2% copper. These new versions show impressive results against corrosion too studies indicate they last about 38% longer before showing signs of rust damage when used near coastlines versus regular galvanized alternatives. Pretty significant improvement for areas where salt air causes so much trouble for metal components.

Ensuring compatibility between high strength nuts and bolts for optimal performance

Mismatched components cause 23% of premature bolt failures in steel frameworks. Proper pairing requires:

- Matching strength grades (e.g., 10.9 bolts with 10 grade nuts)

- Coordinated hardness levels (nut hardness ≤ bolt hardness by 20–30 HB)

- Compatible thread tolerances (ISO 1A/1B for general use vs. ISO 2A/2B for precision joints)

Long term cost savings, durability, and sustainability in modern construction

While high strength bolts cost 40–60% more than standard fasteners initially, they reduce lifecycle costs by:

| Factor | Improvement | Source |

|---|---|---|

| Replacement frequency | 3.7x longer | FHWA 2023 Report |

| Maintenance costs | 52% lower | NIST Study 2024 |

| Scrap rate reduction | 28% | ISO Sustainability Metrics |

The 2025 Recycled Steel Initiative shows high strength bolts made from 85% recycled steel lower embodied carbon by 19 tons per kilometer in bridge projects compared to conventional alternatives.

Table of Contents

-

How High Strength Bolts Work: Principles and Mechanical Properties

- The fundamental principle of high strength bolts: clamping force and preload

- Mechanical properties of high strength bolts: tensile strength, yield strength, and hardness

- Toughness and ductility requirements for reliable structural performance

- Frictional force in bolt connections: role in load transfer efficiency

- Comparison of ASTM A325 and ASTM A490 specifications in real world applications

-

Superior Load Capacity and Long Term Structural Integrity

- How High Strength Bolts Improve Load Distribution in Steel Structures

- Case Study: Load Capacity Analysis in a Multi Span Bridge Using High Strength Bolts

- Data Comparison: Failure Thresholds of Standard vs. High Strength Bolts Under Stress Testing

- Role of Preload in Maintaining Long Term Structural Integrity

- Vibration and Dynamic Load Resistance in Critical Infrastructure

- Friction Type vs. Bearing Type High Strength Bolt Connections

-

Standards, Materials, and Real World Benefits of High Strength Bolts

- Overview of key standards: ISO 898 1, ASTM A325, A490, and A354

- Common materials and grades for high strength nuts and bolts in heavy construction

- Ensuring compatibility between high strength nuts and bolts for optimal performance

- Long term cost savings, durability, and sustainability in modern construction