In the reality of fastener's, industry makes sure that the US and the EU statute are followed. This peice looks into fasteners and how they can meet the regulations while tailoring solutions for various industries.

Introduction

Custom fasteners are crucial for industries like automotive and aerospace. Custom fasteners are much more than simple mechanical parts. These devices are some to simple mechanical devices and are needed to ensure the safety and reliability of complex systems. The US and EU markets have a set of regulations that need to met, making it imperative for businesses to understand the needs while sourcing or producing custom fasteners.

Understanding US and EU Standards

The fasteners regulations in the US and the EU are exhaustive. In the US, The American National Standards Institute (ANSI) and The Society of Automotive engineers (SAE) have put in place laws governing the adequacy and functionality of fasteners. In EU, there is the European Committee for Standardization (CEN) which has similar regulations. These fastener standards include the provision of certain loads, corrosion resistance, and preservation of structural strength.

Why You Should Care About Customization

Custom fasteners provide the ability to personalize a product to a specific application. There are always specific problems in industries that cannot be solved using stock fasteners. Custom fasteners can be made to specific measurements, materials, and even performance goals. For instance, in aerospace, fasteners are required to be able to undergo extreme temperatures and pressures. They must be made in a custom manner, and adhere to both US and EU regulatory standards.

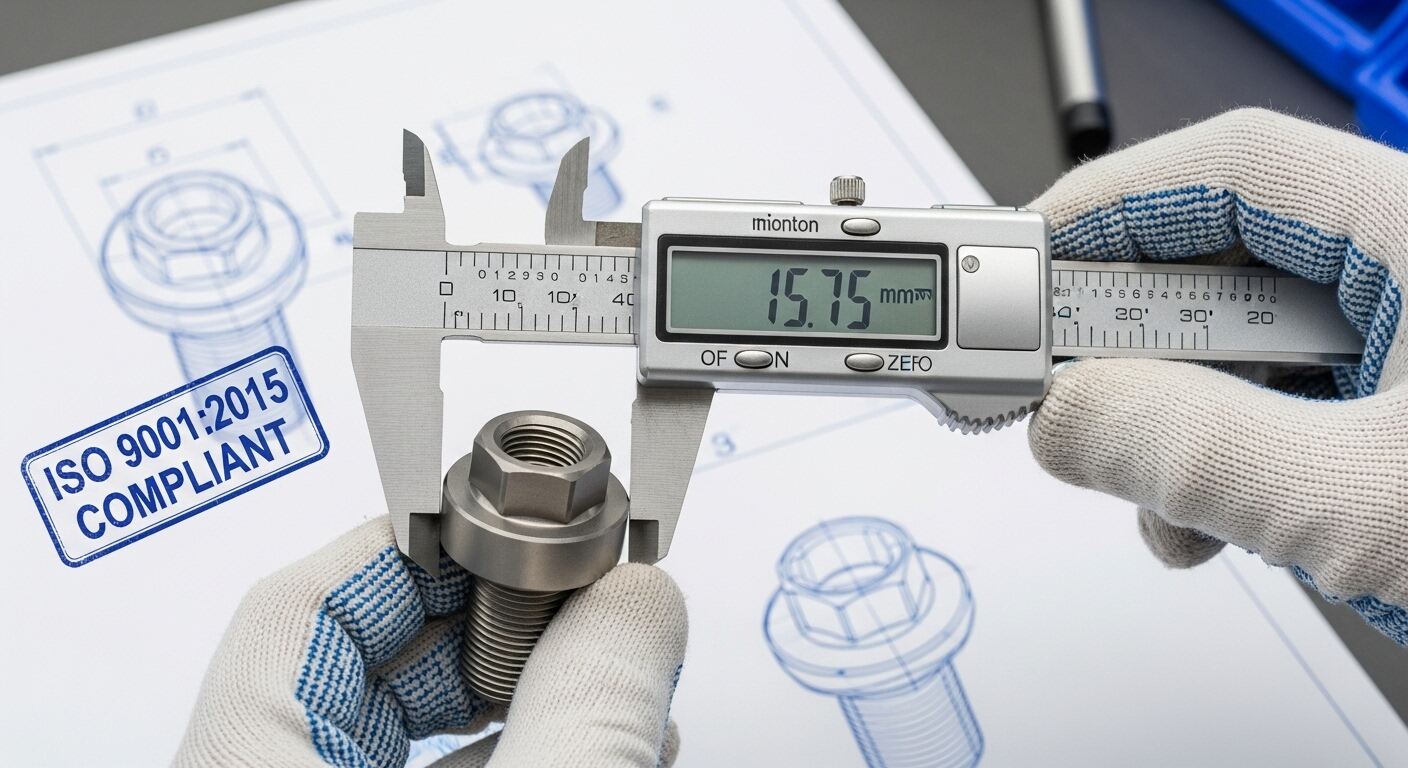

Testing and Assurance of Quality

Many industries and applications have standards which require validation and impose strict control. Compliance requires thorough quality assurance which covers material and product testing. There are also other tests which need to be performed such as tensile strength test, fatigue test, and even corrosive resistance test. All of these tests ensure that custom fasteners do not fall short of the bare minimum standards. Also, especially when entering the US and EU markets, validation with certifying agencies is of utmost importance.

Industry Trends and Future Outlook

The evolution of modern industries and advanced manufacturing technologies like automation and 3D printing have altered the production of custom fasteners. Meeting custom fastener production deadlines and responsiveness to market shifts are now much more achievable. With the rise of advanced manufacturing technologies, there will be more attention to sustainable practices, furthering the custom fastener landscape. Companies that adapt to and utilize the custom fastener production shifts will have the competitive edge to gain global market share.

Conclusion

In conclusion, custom fasteners are critical for companies that operate under strict US and EU guidelines. By understanding these precision regulations, investing in fastener quality assurance, and employing custom styling, manufacturers will thrive in a competitive market. Leveraging current and emerging industry trends will empower the rapid response fastener sector shifts to bolster market demand.