Home >

At Ningbo Yinzhou Gonuo Hardware Co., LTD, we specialize in manufacturing high-quality stud bolts and nuts designed to meet the rigorous demands of various industries worldwide. Our products are engineered for strength and reliability, making them essential components in construction, automotive, and machinery applications.

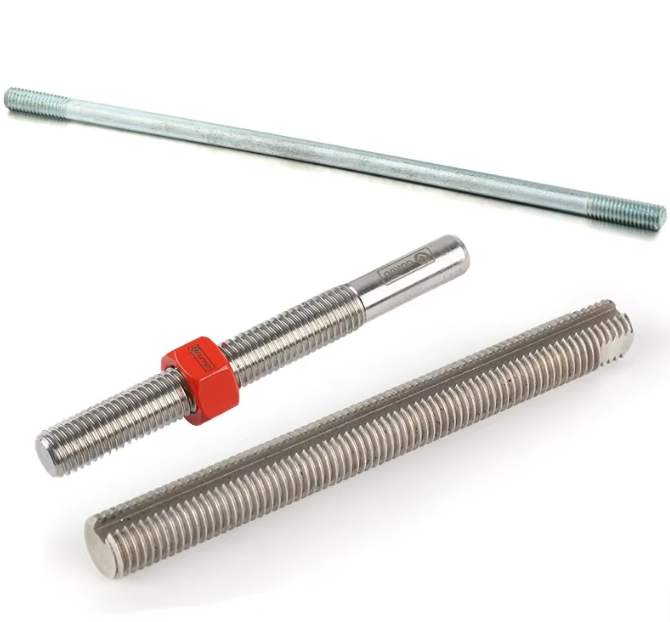

Stud bolts are essential for applications requiring high tensile strength and stability. They are often used in critical connections where safety and performance are paramount. Our stud bolts come in various grades and sizes, allowing us to cater to diverse customer needs. Each stud bolt is manufactured using premium materials, ensuring they can withstand extreme conditions without compromising integrity.

Nuts, on the other hand, are integral to securing fasteners in place. Our nuts are available in different styles, including hex nuts, lock nuts, and flange nuts, each designed for specific applications. We understand that the right nut can enhance the performance of the stud bolt, which is why we offer a comprehensive range of options to ensure compatibility and effectiveness.

In addition to our standard offerings, we excel in providing customized fastener solutions. Our dedicated engineering team works closely with clients to develop products tailored to their specific requirements. This includes adjustments in size, material, and design to meet unique application challenges. Our commitment to innovation and quality has earned us a reputation for excellence in the fastener industry, particularly in demanding markets like the US, Germany, and Japan.

Furthermore, our production facility is equipped with advanced technology that allows us to maintain high efficiency while ensuring precision in manufacturing. This means we can handle both small and large orders without compromising on quality or delivery timelines. Whether you need a few pieces or thousands, we are equipped to meet your demands promptly.

At Gonuo, we believe that our success is tied to our customers’ success. Therefore, we prioritize building long-term relationships based on trust, mutual benefit, and adherence to contracts. Our customer-centric approach ensures that we are always ready to support our clients with the best possible solutions for their stud bolt and nut needs.